Why Choose Quintessential Plumbing?

It’s simple:

-

- We Love People & Plumbing

- Lifetime Workmanship Warranty

- Totally Dependable

- Fixed Pricing

- 24 / 7 Emergency Response

- Reputable Plumbers with over 100 reviews online

$100 off hot water systems

get job discount

Book online to receive $50 off

get job discount

Blocked drain services from $88

get job discount

Definition and Description

Plumbing is the arrangement of pipes, valves, valve assemblies, drains fittings, and devices setup in the construction for the giving out of water for heating and washing, drinking, and the taking out of waterborne wastes having the basic plumbing knowledge base is a good idea to have. It is also the skilled deal of working with tubing, plumbing fixtures and pipes in such systems. The plumber is somebody that repairs or installs plumbing fixtures and equipment and piping systems like the backflow preventers and the water heaters. The industry of plumbing is the substantial part and the basic of every developed nation because of the need for spotless or clean water, transport of wastes and for sanitary collection. Plumbing is normally identified from the water supply and the sewage systems and in this regard a plumbing system operates a building, while the water and the sewage systems served a mass of buildings.

The word “plumbing” came from the Latin word “plumbum” for lead since pipes were once composed of lead. Plumbing is also a term used for the so called shell code, because of the occurrence of pipelines that nourish the output of a program to an input of the other. Generally, plumbing is the pipe, together with the tanks, stopcocks, taps, joints and some other fixtures of the gas, water, or sewage system of the house or the building.

History of Plumbing: The Creation of Internal Plumbing

The story of plumbing is exceptionally long and did not always involve the indoor or internal plumbing. While we usually take modern inside plumbing for granted, this has not always been so suitable. And so, when was the indoor plumbing created? The most central advancements in the history of plumbing occurred above several millennium to supply to what we have now as the modern day plumbing.

4000 – 3000 BC – The archaeologists unearthed the first ever water pipes in India at the Indus River, date back to the year of 4000-3000 B.C. The Egyptian monarch Menes also supported the thriving civilization by building irrigation ditches, basins and canals.

2500 BC – The Egyptians cultivate copper pipes just in order to construct sewage systems inside those pyramids and sophisticated bathrooms with irrigations. Believing that the dead required clothing, food, and some other essentials during the afterlife, the Egyptians put in bathrooms in crypt as well. During this time, the sitting toilets appeared in Harappa civilization that is now India, even though it is not exactly known who formulated a toilet.

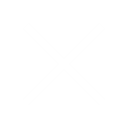

1500 – 1000 BC – During the supremacy of the King Minos, the citizen of Crete made elaborate sewage dumping and the drainage systems with the underground channels. In this same era, the first ever flushing toilet has been invented, complete with the wooden seat. The Archeologists have also located a bathtub similar to cast-iron ones in America from the late nineteenth century.

710 BC – The Assyrian king, Sargon the Great, invented the first ever shower by having his slaves on the ladders pouring water over him during his bathing time.

500 BC to 455 AD – Roman Empire cultivated complex ancient plumbing methods together with the aqueducts, public baths, underground sewers, lead and bronze piping systems, and also the marble fixtures. About 52 AD, the Rome boasted an anticipated 220 miles of those aqueducts, water channels and pipes used to supply to baths, public and homes wells. These water channels had been powered by gravity or magnitude and had been carried 300 gallons fresh water for the people of Rome.

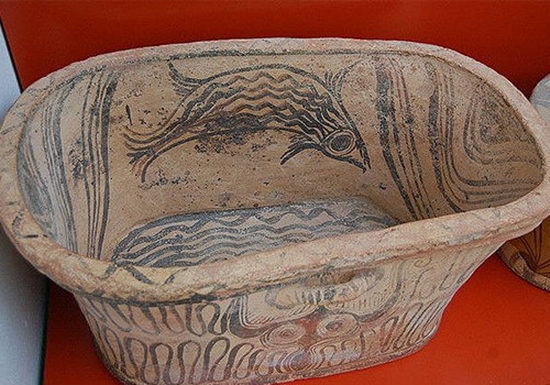

1596 – Sir John Harrington who is known as the godson of a queen, Queen Elizabeth I designed the first ever flushing toilet to be offered to his godmother and it is initially used in Richmond Palace. He made the flushing water closet also for himself in his home. Its contraption included the bowl, the seat and the water cistern at the rear of the seat.

1644 – The France King, King Louis XIV, ordered the making of the cast-iron major plumbing line. This line carried the water about 15 miles from the station of the plumbing to the fountains of the palace as well as to its surrounding areas.

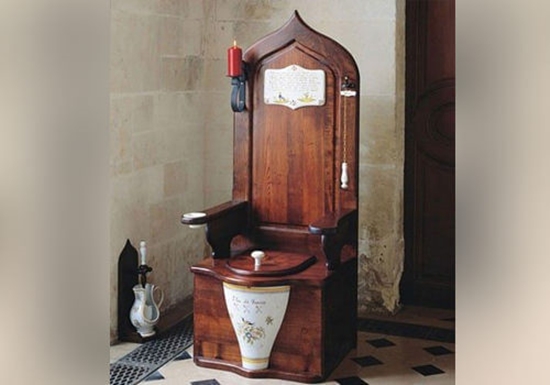

1775 – The modern toilet prototype was first ever developed by Alexander Cummings Jr., a Scottish inventor. The water closet of Sir John Harrington was able of flushing; however, it didn’t have the water trap. The prototype of Cummings included the S trap, which had the sliding valve in between a trap and a bowl that permitted some water to remain in the bowl. And so, the water does not anymore smelled like sewage, plus, the bowl can be easily maintained and cleaned every after use.

1804 – Philadelphia had been the first ever city that replace wholly to the cast iron pipes in making their new systems of water delivery.

1810 – The English Regency showers were first set up in the 1810 A.D. Its water is plumbed by a nozzle and sprayed at shoulder point. The water had been then collected and then pumped through a shower again.

1829 – Boston’s Tremont Hotel was the first ever hotel of its type to feature the indoor plumbing for their guests. There are 8 water closets that were made by Isaiah Rogers. Up to 1840, the indoor water closets had been commonly seen in the houses of the rich, the famous and in luxury hotels as well. Soon, the soap was commenced during the bathing and it catches on for sanitation purposes.

1833 – The White House had been initially plumbed with the running water on their main floor. The upstairs plumbing was then introduced when their president, Pres. Franklin Pierce was inside the office.

1885 – Chicago had been the first ever city in the state to have their comprehensive sewer system.

1891 – Thomas Crapper untested his valve and the siphon design, upgrading the current toilet in the progress. His work modernized the present concept of plumbing.

1904 – John C. Flood had initially founded in 1904 in Washington, D.C. This company started serving Maryland and Northern Virginia as it grew.

1910 – The lofty water tank turn out to be the most updated closed toilet water tanks and the bowl that lots of people have now in their bathrooms.

1966 – Because of the shortage of copper right after the wartime requirements, the non-metallic and the plastic piping systems had been initially introduced for toilets use.

1986 – The first ever sensor-flushing toilets had been introduced in the state of Japan.

2003 – The ICC or International Code Council was formed by the union of the three model construction code agencies. The Council helps to make sure that every future developments and actions followed the strictly enforced standard and code in all of their projects.

The present day plumbing is now advanced. And not everyone had their time to become a plumbing expert and if you do not have that sufficient for inspect of your own plumbing system for possible changes repair, call the plumbing experts in your vicinity now!

Water Distribution Pipes

The water pipe is referring to any tube or pipe styled to move delighted drinking water to their consumers. The varieties take in the bigger diameter main pipes that supplied the whole towns, the smaller branch lines which supplied group or street of buildings, the small diameter pipe is located within the individual buildings. The materials commonly utilized for constructing water pipes include the cast iron, copper, steel, concrete and the PVC or polyvinyl chloride.

When the water is being treated before the distribution or during the instances of use depending on the context, with the well designed and the planned water distribution networks, the water is usually treated just before the distribution and at times also chlorinated, just in order to shun from possible recontamination on its way to the final user. The ranges of water pipes contain the bigger diameter main pipes, that supplied the whole towns, the smaller branch lines which supply the group or the street of buildings, or the small diameter pipe situated within individual buildings. The water pipes may vary in sizes from the giant mains up to the 3.65m in diameter up to small 12.7mm pipes utilizing in feeding individual outlets within the building. The materials are commonly used to make the water pipes including PVC or polyvinyl chloride, steel, cast iron, copper, and in the older systems fired or concrete clay. Joining the individual water pipe length to create extended runs will be possible with the nipple, compression, soldered joints and flange.

Advantages:

- The water may be transported by the use of gravity.

- The water quality is being preserved when compared to the trenches.

Disadvantages:

- It has high initial investment.

- It has expensive maintenance and operation that needs for regular reinvestments so it can maintain the infrastructure.

- Danger of recontamination.

- Danger of loss of water through leakage

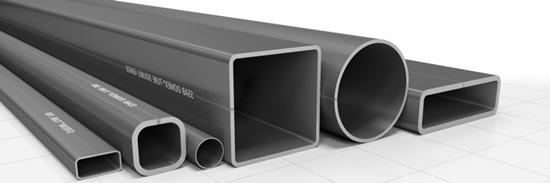

Types Of Pipes:

The pipes come in numerous kinds and sizes. These may be divided into 3 main categories: cement pipes, plastic pipes and the metallic pipes. The metallic pipes include the steel pipes, cast iron pipes and the galvanize iron pipes. The cement pipes include the asbestos cement pipes and the concrete cement pipes, while the plastic pipes include the only the PVC or the plasticized polyvinyl chloride.

Steel pipes – these are comparatively costly, but these are considered as the most durable and the strongest of all the water supply pipes. These can withstand the high water pressure, they can be easily welded, this come in long and convenient lengths than most of other pipes and it incur lower transportation costs and installation as well.

Galvanize steel or iron pipe – this is the usual piping material of the plumbing business for the passage of wastewater and water. Even though these are still used from all around the world, its fame is declining. The utilization of iron or galvanized steel as the conveyer for this drinking water is really problematic where the water flow is just static and slow for ages of time since it can cause rust from the internal corrosion. The galvanize steel or the iron piping can also provide the unpalatable taste and also the smell to water conveyed beneath corrosive conditions.

Cast iron pipes – these are well suited and quite stable for the high water pressure. But, the cast iron pipes had been heavy, which makes it not fitted for inaccessible spots because of transportation problems. Additionally, because of their weight they usually come in short length increasing the costs for jointing and layout.

Concrete cement and the asbestos cement pipes – these are costly but non-caustic by nature. The advantages are that these are tremendously durable and strong. But, being heavy and bulky, they are harder, pricier to handle, to install and to transport.

PVC or Plasticised polyvinyl chloride pipes – these are non-corrosive, very light and therefore easy to deal with and transport. Nevertheless, they are come in longer lengths and are strong that lower the transportation and the installation costs. But, these are prone to some physical damage when being exposed over ground and will become brittle if these are exposed to the ultraviolet light. Additionally, the problems connected to the contraction and expansion of PVC, these materials will deform and will soften if these will be exposed to temperatures that are above 65 °C.

Cost Considerations:

The installation costs will make up the major part of its total project costs. The differences in the amount of an actual pipe don’t change the whole cost of a project much. But, the following factors must be taken into consideration concerning the choice of pipes and the installation costs:

Pipe strength: If a kind of pipe will require special bedding that can withstand external pressure while the other pipe doesn’t, the choices will impact installation costs notably.

Weight of a pipe: The pipe that is light in weight may be handled faster and easier.

Ease of assembling: The push-on joints may be assembled even faster than the bolted joints.

Applicability:

The water pipes are needed almost everywhere particularly for the drinking water distribution. Its’ most durable and the most robust type of water pipe is possibly made from cement. However, because of their heavy weight, this is expensive and difficult to install. The PVC pipes are so much easier to install, much lighter, and therefore particularly fitted for remote areas which are hard to access.

What is the variation between a Pipe and a Tube?

People are using the words pipes and tubes interchangeably, and they thought that both are just the same. But, there are significant variations between pipes and tubes and here are they:

What are Pipes?

The pipe is the round tubular section with the round cross sections for the passage of products. These products include gas, pellets, powders, fluids and many more and it is designated by the nominal pipe size which represents the rough suggestion of a pipe conveyance capacity.

The most essential mechanical parameters for the pipes are its pressure rating, its yield strength, and its ductility. The standard blending of pipes Nominal Wall Thickness and Pipe Size (schedule) are being covered by ASME B36.19 and ASME B36.10 specifications (carbon and alloy pipe, and the stainless steel pipes).

What are Tubes?

The word tube pertains to the rectangular, squared, oval or round hollow section that is measured by an outside diameter and the wall thickness is expressed in millimeters or inches and are being used for used for mechanical applications, for instrumentation systems and for pressure equipment.

10 Basic Differences of Pipes and Tubes

Key Dimensions:

- PIPES – The main dimensions for the pipe is its outer diameter or OD together with a wall thickness or WT. OD minus 2x WT (SCHEDULE) identified ID or inside diameter of the pipe, which identified the liquid aptitude of a pipe. The NPS will not match with the actual diameter, it is the rough indication.

- TUBES – The main key dimension for the steel tube are its outside diameter or OD and its wall thickness or WT. These parameters had been expressed in millimeters or inches and express the real dimensional value of a hollow section.

Wall Thickness:

- PIPE – The steel pipe thickness is designated with the “Schedule” value. The two pipes of unlike NPS and similar schedule have distinctive wall thicknesses in millimeters or inches.

- TUBE – The WT or wall thickness of the steel tube has been expressed in millimeters or inches. For tubing, a wall thickness is being measured also with the gage nomenclature.

Shapes:

- PIPE – Round only

- TUBE – Round, oval, rectangular, and square

Production range:

- PIPE – Extensive (from 80 inches and up)

- TUBE – The narrower range for tubes (until 5 inches), bigger for steel tubes of mechanical applications.

Tolerances such as roundness, straightness, and dimensions:

- PIPE – Tolerances are being set, but instead loose. The strength is not their major concern.

- TUBES – The steel tubes are formed to very strict tolerance. The tubulars undergo some dimensional quality checks, like the roundness, wall thickness, straightness, surface, during the developing process. The mechanical strength is the main concern for tubes.

Production Process:

- PIPE – These are usually made to supply with the highly automated and the effective processes, examples are pipe mills produced on the continuous basis and then feed distributors stocks from around the world.

- TUBE – The manufacturing is more laborious and lengthy.

Delivery time:

- PIPE – Can be shortened

- TUBE – Normally longer

Market price:

- PIPE – It is relatively lower in price per ton when compared with steel tubes.

- TUBES – It is higher because of lower mills productivity in an hour, and because of stricter requirements with connection to inspection and tolerances.

Materials:

- PIPE – The wide range of resources is available.

- TUBE – The tubing are available in low alloy, carbon steel, nickel-alloys and stainless steel; and the steel tubes for its mechanical applications are normally of carbon steel.

End Connections:

- PIPE – The most familiar are beveled, screwed ends and plain.

- TUBE – The threaded and the grooved ends can be availed for a quicker connection on site.

Reference:

Definitions for plumbingˈplʌm ɪŋplumb·ing. (n.d.). Retrieved July 03, 2020, from https://www.definitions.net/definition/plumbing

John C. Flood, I. (2020, March 31). History of Plumbing Timeline. Retrieved July 03, 2020, from https://www.johncflood.com/blog/general/history-of-plumbing-timeline

Author/Compiled by Eytan Gur. (2019, May 16). Water Distribution Pipes: SSWM – Find tools for sustainable sanitation and water management! Retrieved July 03, 2020, from https://sswm.info/sswm-university-course/module-2-centralised-and-decentralised-systems-water-and-sanitation-1/water-distribution-pipes

S., W. (n.d.). Retrieved July 03, 2020, from http://www.wermac.org/pipes/pipe_vs_tube.html

Related Pages: